| A – B | - Air Motor: A slow speed hand piece without integral reduction gears or attachments

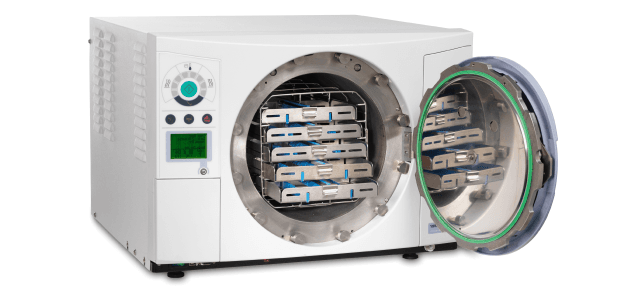

- Autoclave: A steam sterilizer that kills living organisms. Temperature is raised to (135ºC) while the pressure is raised to 30 PSI.

- Bearing: A high precision part used to support rotating parts with very low friction.

- Bur: A rotary dental instrument held and revolved in a hand piece. Used to remove carious material within decayed teeth to reduce decayed or fractured hard tissues, to form the design of the cavity preparation, and to finish and polish teeth and restorations. Can be made of high-speed steel, carbide or diamond coated material.

|

| C | - Chip Air: Air supplied to the cutting surface to cool the tooth and flush chips and residual material resulting from the removal of a decayed tooth surface.

- Chuck: A mechanism used to change a bur by pressing a button or by raising a latch lever.

- Contra Angle: An attachment used with a straight or slow speed motor that changes the desired angle to better reach areas in the oral cavity, which are difficult to access.

- Coupling: There are four types of standard hand piece couplings. They include the 2-hole (also called a Borden fitting); 3-hole and 4-hole. The 4-hole (also called a Midwest Connector) is the most popular connector. In a 4-hole connector, the holes are (1) drive air, (2) chip air, (3) water and (4) ex

|

| D – E | - Drive Air: The air supply used to power an air-driven dental instrument.

- “E” Type Motor: Motor which has a standardized nose attachment for fitting of straight or contra angles hand pieces.

- Exhaust: The air discharged from a dental hand piece.

- Fiber Optic Hand piece: A hand piece which incorporates a fiber optic light source.

|

| H | - Hand piece: A handheld device, which engages rotary instruments for cutting, cleaning or polishing the teeth. A hand piece can be air driven or electric.

- High-Speed Hand piece: A hand piece that operates at a speed greater than 200,000 RPM

|

| L | - Low-Speed Hand piece: In general, any hand piece used at speeds less than 200,000 RPM. Sometime referred to as Slow-Speed Hand piece.

- Lubricant/Cleaner: A liquid applied to moving parts of a hand piece or attachment in order to reduce friction, heat, or wear, or applied to surfaces in close contact to prevent them adhering to one another. Also includes a solvent for cleaning.

|

| P – R | - Prophy hand piece: A prophy angle accepts screw-in brushes on cups or snap-on cups.

- Quick-Disconnect: A hand piece attachment or coupling designed to allow easy separation of the hand piece from the supply tubing.

- RPM: Revolutions per minute (RPM) is often used to describe the types of hand pieces. Air motor is 20,000 RPM or less is used; Electric motor 40,000 RPM or less; and for high speed 400,000 RPM and greater.

|

| S – T | - Straight Hand piece: Same as slow speed hand piece.

- Turbine: Located in the head of the high-speed hand piece, it rotates by the use of compressed air. A high-speed hand piece typically consists of five major parts: spindle (or centre shaft); chuck; impeller; bearings and “O” rings.

|